80×120 Wastewater Facility Steel Buildings: 9,600 Square Foot of Pure Productivity

Because every beam is factory-drilled, bolts drop straight in; installers waste no time reaming holes. Precision means faster dry-in, protecting sensitive electronics from wind-driven rain.

Owners keep neighbors happy too. Galvanized panels pair with tasteful trim, giving municipal sites a professional look that builds community trust.

Pre-Engineered Steel Building Kits Drive Predictable Building Price

Our pre-engineered steel building kits are cut by robots, locking material totals long before ground breaks. That certainty locks the building price, shielding budgets from market swings. Detailed drawings accompany every truckload, so ironworkers assemble frames like life-size puzzles – no field drilling required.

Speedy erection shortens crane rentals and lowers insurance coverage days, pushing soft costs down.

Once enclosed, trades follow fast. Electricians hang cable trays, plumbers mount pipe racks, and operators begin dry runs – all while concrete crews elsewhere still wait on block cures. Time is money; this kit keeps both in check.

Meeting Local Building Codes Without Delays

Permitting headaches stall many building projects, but stamped plans that satisfy local building codes glide through review. Our engineers factor wind, seismic, and fire safety from the first sketch. Jurisdictional checklists become quick approvals, not red-line marathons.

Clear code compliance also lowers insurance premiums, freeing dollars for process upgrades.

Finally, inspectors appreciate organized jobsites. Bundled bolts, labeled panels, and tidy weld logs mean fewer re-checks and a smoother path to occupancy.

120 × 80 Steel Buildings Engineered to Withstand High Winds

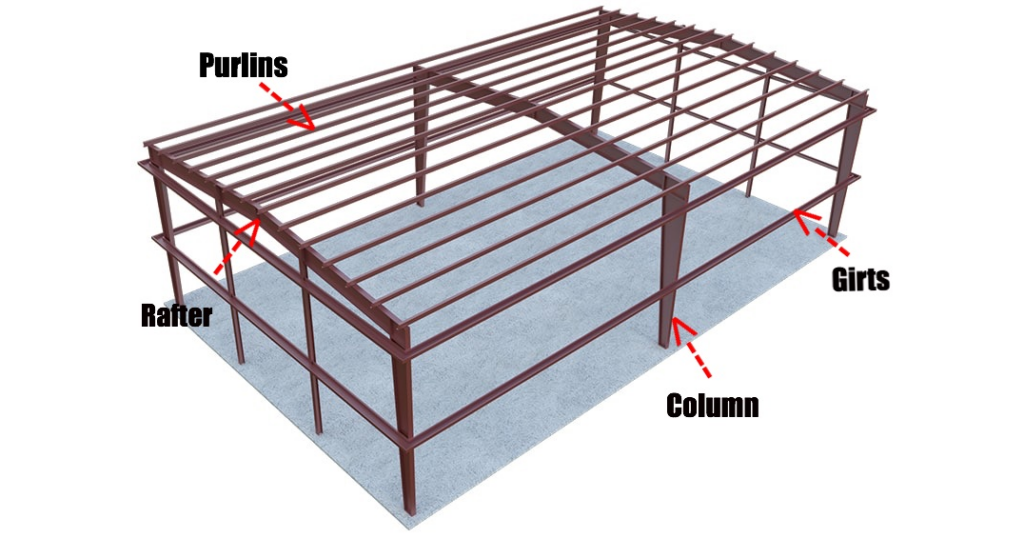

Gusty coastal sites need muscle. 120 x 80 steel buildings use deep-rib roof panels, stout purlins, and moment-resisting frames to withstand high winds that topple a fragile wooden structure. Clip spacings match regional hurricane maps, so roof sheets stay put when storms roar.

Vertical seam panels lock tight against uplift while letting rain race away. Low 1:12 roof slopes maximize vertical space. Deep-rib panels resist seismic forces, too.

Add optional impact-rated doors and louvers for maximum storm resilience. When sirens fade, the building stands ready for business instead of waiting for tarps.

When it comes to construction projects, there are few things more frustrating than delays caused by failing inspections or non-compliant code issues. Not only do these setbacks cost time and money, but they can also put a strain on relationships with clients and contractors.

Strength and Safety in an 80×120 Wastewater Facility Metal Buildings Shell

Process pumps vibrate; blowers pulse; chemicals corrode. 80×120 wastewater facility metal buildings combat all three with rigid frames, heavy-duty anchor bolts, and factory coatings that shrug off chlorine mist.

Rigid bracing limits sway, protecting pipe joints from fatigue. Stainless fasteners resist rust where wash-downs spray.

Long-life strength equals fewer emergency repairs over the long term, giving operators crucial peace of mind during high-flow events.

Snow-Ready Design for Heavy Snow Regions

Northern utilities can’t shut down for blizzards. A 120 x 80 metal building kit arrives with roof loads sized for heavy snow drifts plus equipment weight. Deep-leg rafters and tall eaves keep piles from pressing against wall panels.

Snow-deflector trim channels meltwater away from doors, preserving gaskets and sensors through freeze-thaw cycles.

Inside, ceiling fans push trapped heat downward, hastening roof melt and reducing ice dam risk. Temperature balance keeps both staff comfort and structural safety high.

Smart Building Materials Deliver Superior Cost Effectiveness

Galvanized girts, painted panels, and closed-cell insulation resist chemicals better than masonry paint ever could. These premium building materials slash repaint cycles, boosting cost effectiveness year after year.

LED fixtures rated for moist environments sip power while brightening work zones. Daylight strips further cut electric bills and raise morale.

Over decades, energy and maintenance savings dwarf the small up-front premium, proving why steel beats wood or block in wastewater duty.

Flexible Building System Eases Future Expansion

Regulations change, flows grow, and technology shifts – but a modular building system keeps pace. End walls unbolt for fast length additions, while roof-curb kits accept new odor scrubbers without torching frames.

Interior mezzanines bolt to main columns, adding office or lab floor in weeks, not months. This flexibility protects earlier investments and keeps the plant agile, avoiding costly new land acquisitions.

In addition to the energy and maintenance savings, steel also offers a flexible building system that allows for future expansion. This is particularly valuable in the wastewater industry, where regulations often change and flows can increase over time.

Turnkey Metal Building Kit Simplifies Every Trade’s Schedule

Each metal building kit ships with numbered clips, pre-cut openings, and bolt packs grouped by phase. Ironworkers finish frames quickly; electricians run tray straight through rafters; plumbers drop pipe racks before weather flips.

Sequenced deliveries clear yard space, preventing clutter and lost hardware. Streamlined workflow shrinks build calendars, ensuring new capacity comes online before peak-demand seasons strain aging infrastructure.

Choose Maverick – The Leader in 80×120 Wastewater Facility Buildings Offer

Maverick’s 80×120 wastewater facility steel buildings merge durability, speed, and value like no other supplier. Our kits meet code, stand strong, and keep costs fair – delivering everything modern building projects demand.

Responsive teams answer questions fast, refine layouts, and coordinate freight so nothing slips. After erection, warranties and live tech support continue your peace of mind for decades.

Don’t gamble on critical infrastructure. Contact Maverick Steel Buildings today to lock pricing, pick options, and claim a structure that outperforms for the life of your plant.

WHY CHOOSE MAVERICK STEEL BUILDINGS

Building Custom Metal Structures Is Our Specialty.

Fast Delivery

Short turnaround time for drawings.

Full Service

Installation & Coordination in the southeast USA.

Foundation Drawings Included

Customers always receive the foundation drawings.

Premium Quality

Premium Quality Steel & parts.

Safety & Durability

Fire resistant metal buildings last a lifetime.

Cost savings

Much more cost-efficient than traditional wooden structures.

No hidden cost

100% complete quotes.

Quick & Easy

Faster and easier to construct that traditional methods.

Customizable

Attractive building finish and a wide variety of options and colors.

Maintenance Free

No need to paint or patch.

100% American Made Steel

Supporting a network of American businesses.

Environmentally Friendly

25-35% of our materials are recyclable.

Price My Building

Don’t want to wait?

Call now!

| Monday | 09:00 – 17:00 | |

|---|---|---|

| Tuesday | 09:00 – 17:00 | |

| Wednesday | 09:00 – 17:00 | |

| Thursday | 09:00 – 17:00 | |

| Friday | 09:00 – 17:00 |