Unleash Capacity with 150×300 Data Center Steel Buildings

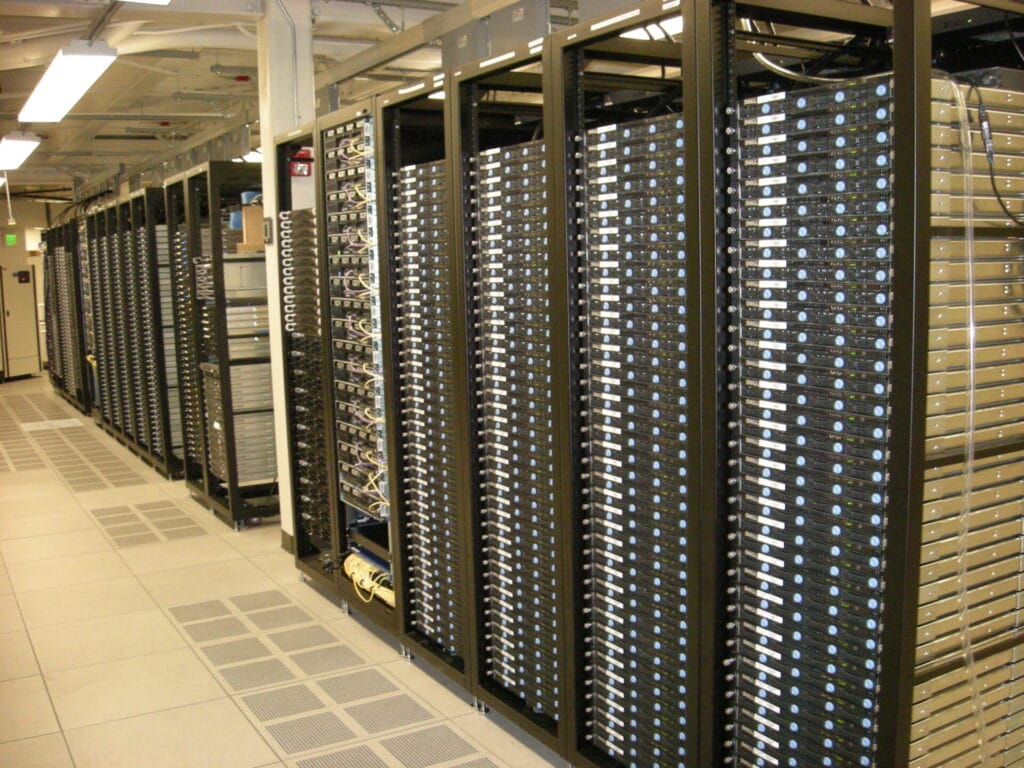

A 150×300 data center steel building gives you 45,000 square feet of open floor space – plenty for dense server rows, battery rooms, and a network operations center. Clear spans remove the issue of interior posts, so hot-aisle layouts stay smooth and airflow moves freely.

That openness also lets forklifts glide in straight lines, speeding installs and keeping technicians safe. Wide walls welcome big louvers and dock doors without structural headaches.

The footprint scales for future tech, too. When rack power doubles, you still have room to grow without adding a second site or squeezing hardware.

Speedy Builds: 150×300 Data Center Metal Buildings and Your Construction Timeline

Nothing eats budgets like delays. 150×300 data center metal buildings – sometimes typed as 150×300 data center metal building – ship pre-cut and numbered, so crews bolt them up fast.

Shorter assembly shrinks the construction timeline, slashing downtime and wasted money. Faster dry-in protects gear from rain and theft, letting you place servers sooner.

Because these metal buildings are erected in weeks, our customers see live services while rivals still pour concrete. Speed here turns into market share there.

Pre-Engineered Steel Buildings Reduce Construction Costs

When it comes to construction projects, keeping costs under control is a top priority for any business or organization. Pre-engineered steel buildings offer an innovative solution to minimize expenses while maintaining quality and efficiency.

These structures are designed with precision and custom-built to meet your specific needs, delivering long-term value and durability. Their streamlined construction process not only saves time but also significantly reduces the financial strain often associated with traditional building methods.

Below are some key ways pre-engineered steel buildings help trim costs and ensure your project stays on budget.

- Precision factory modeling reduces waste and eliminates unexpected rework.

- Pre-engineered steel buildings come with labeled parts and pre-punched holes, simplifying assembly.

- Accurate designs reduce steel usage and material costs.

- Predictable loads allow for shallower footing designs, lowering concrete expenses.

- Early cost predictability ensures tighter bids and smoother financial planning.

Structural Integrity for Steel Structures in Extreme Weather Conditions

Hurricanes, blizzards, and quakes test any shell. Rigid steel structures pass with ease, thanks to high-strength frames and solid diaphragm action.

Their structural integrity guards servers, batteries, and fuel tanks when winds howl or the ground moves. Pre-engineered bracing soaks up lateral force without cracking walls.

Factory coatings fight rust in coastal air, while deep-rib panels shed heavy snow. Your data center stands tall through extreme weather conditions year after year.

Smart Ventilation Systems for High Quality Airflow

Servers hate heat. Purpose-built ventilation systems in each bay sweep hot air away fast, keeping chips cool and power bills down.

Tall clear spans let ducts run straight, reducing bends that rob efficiency. Filters sit at floor level for quick swaps, boosting uptime.

Every element meets high-quality control checks before shipping, so installers spend less time tweaking and more time turning switches on.

Long-term Cost Saving and Cost-Effective Operation

Energy and staff payroll stack up over decades. Tight seals, thick insulation, and reflective roofs lock in long-term savings on power.

Efficient layouts shorten cable runs, slashing copper and future repair bills. Smart lighting cuts electric waste in aisles with motion sensors.

All those choices make the facility truly cost-effective. Over time, the pennies saved each hour balloon into serious dollars – real cost savings you can measure.

Streamlined Construction Time and Smooth Construction Project Flow

Clear plans, labeled bundles, and single-source supply speed every task. Shorter construction time frees crane crews early and locks in earlier revenue.

One point of contact means faster answers when questions pop up, so work never stalls waiting for approvals.

A tidy yard also matters. With fewer loose parts, the whole construction project stays clean and safe, cutting hazards and boosting morale.

Meeting Maintenance Requirements and Reducing Labor Costs

When it comes to operating a facility, cutting down on maintenance costs can have a huge impact on your overall budget and efficiency. By choosing materials and design features that are built to last, you can save time, money, and resources in the long run.

Every decision you make to reduce upkeep helps free up your team to focus on what matters most, without the constant hassle of repairs or replacements.

- Steel wall panels prevent common issues such as mold, termites, and rot, ensuring lasting durability.

- Long-lasting paint systems reduce the need for frequent touch-ups, saving time and resources.

- Wide overhead doors improve accessibility, allowing equipment to be serviced quickly and efficiently.

- Lower maintenance demands help minimize the need for large maintenance crews.

- Reduced upkeep and labor costs contribute to maintaining a lean and reliable operating budget.

Flexible Building Kits Compared to Traditional Methods

Modular building kits stack, splice, and swap parts in days, compared to traditional block or tilt-wall that drags on for months.

Need expansion? Remove an end wall, bolt on new frames, and match roof lines – no jackhammers, no rubble.

Steel buildings offer true agility. They adapt to new cooling tech, higher rack density, or even office pods without tearing the shell apart.

The Versatile 150×300 Steel Building Powers Every Mission

A 150*300 steel building hosts far more than servers. Its width suits film studios, indoor sports, or staging lines for e-commerce giants.

That same shell can be divided into cold storage, testing labs, or training rooms with simple framed walls. Your investment works beyond one use case.

Because metal buildings share bolt patterns, mezzanines, catwalks, and cable trays can be swapped across bays quickly. Versatility today keeps tomorrow’s choices wide open.

Choose Maverick – Your Partner for 150×300 Data Center Steel Buildings

When uptime, speed, and savings matter, trust Maverick’s pre-engineered steel buildings. Our expert team crafts full steel building packages tuned to local codes and load demands.

We guide you from permits to punch-out, hitting dates, shaving waste, and protecting budgets every step.

From industrial and commercial facilities to agricultural and institutional buildings, Maverick Steel Buildings has been providing top-quality steel structures for many years.

Ready to own the best 150×300 data center metal building on the market? Contact Maverick Steel Buildings today for a fast quote and see how our high-quality kits turn bold plans into reliable performance.

WHY CHOOSE MAVERICK STEEL BUILDINGS

Building Custom Metal Structures Is Our Specialty.

Fast Delivery

Short turnaround time for drawings.

Full Service

Installation & Coordination in the southeast USA.

Foundation Drawings Included

Customers always receive the foundation drawings.

Premium Quality

Premium Quality Steel & parts.

Safety & Durability

Fire resistant metal buildings last a lifetime.

Cost savings

Much more cost-efficient than traditional wooden structures.

No hidden cost

100% complete quotes.

Quick & Easy

Faster and easier to construct that traditional methods.

Customizable

Attractive building finish and a wide variety of options and colors.

Maintenance Free

No need to paint or patch.

100% American Made Steel

Supporting a network of American businesses.

Environmentally Friendly

25-35% of our materials are recyclable.

Price My Building

Don’t want to wait?

Call now!

| Monday | 09:00 – 17:00 | |

|---|---|---|

| Tuesday | 09:00 – 17:00 | |

| Wednesday | 09:00 – 17:00 | |

| Thursday | 09:00 – 17:00 | |

| Friday | 09:00 – 17:00 |