100×200 Data Center Steel Buildings – 20,000 Square Feet of Possibility

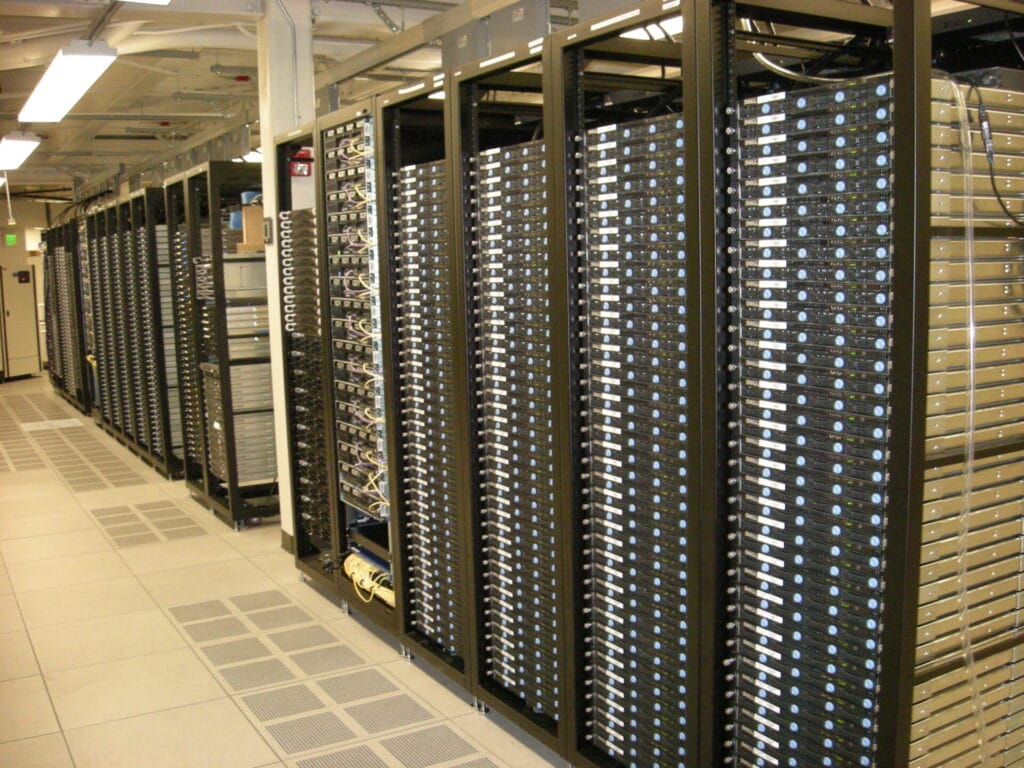

A 100×200 data center steel building delivers a full 20,000 square feet of clear-span interior – more than enough room for dense server racks, support offices, and backup generators. The open floor eliminates posts, giving planners freedom to arrange hot- and cold-aisle layouts without obstacles.

Wide service lanes keep forklifts and cable carts moving safely during installs or refreshes. Future growth is simple: bolt on a mezzanine, drop in battery rooms, or widen containment pods – no major demolition required.

With this footprint, you can host mission-critical IT today and still have space for tomorrow’s high-density hardware, all under one durable roof.

100×200 Data Center Metal Buildings Outperform Traditional Options

Speed matters when servers sit idle. 100×200 data center metal buildings arrive as precision parts that bolt together in weeks, eclipsing slower masonry work.

The rigid steel frame shrugs off heavy roofs, cable trays, and mechanical decks without sagging. That strength translates to long life and lower maintenance budgets.

Because the shell is non-combustible and pest-resistant, insurance premiums drop while uptime climbs. Faster timelines plus lasting durability give your operation a running start over facilities stuck in concrete cure cycles.

Pre-Engineered Metal Buildings Cut Delays and Surprises

Every Maverick kit starts as an advanced 3-D model. These pre-engineered metal buildings ship with holes punched and parts labeled, so crews never waste hours drilling on site.

Tight tolerances ensure perfect fits the first time, preventing costly rework and inspection delays. Even complex penetrations for ducts, fiber, and busways are planned up front.

With the structural math settled at the factory, local inspectors approve drawings faster, and your critical path moves smoothly from delivery to dry-in.

A Steel Building Kit Engineered for Heavy Data Loads

Servers, batteries, and rooftop chillers add weight quickly. Our steel building kit uses wide-flange columns and deep-web rafters to carry those loads with ease.

Factory coating guards every beam against moisture and airborne chemicals. Galvanized secondary framing further protects from corrosion over decades of constant HVAC cycling.

When hardware footprints change, the kit’s modular bays accept new mezzanines or hanging cable ladders without over-stressing core members – true flexibility built in at day one.

- Factory-applied coating protects primary beams from moisture and chemical exposure, ensuring long-term durability.

- Galvanized secondary framing resists corrosion through decades of HVAC system operation.

- Modular design allows seamless integration of new mezzanines, cable ladders, or hardware adjustments.

- Designed for long-term flexibility and adaptability to accommodate evolving operational needs.

Serving Both Data Halls and Distribution Centers

Need space for edge servers and last-mile shipping? This kit scales to hybrid uses that include tech zones and distribution centers under one roof.

The clear floor welcomes tall pallet racks beside climate-controlled cages, keeping fulfillment close to compute power for lightning-fast logistics.

Loading docks, drive-in doors, and knock-out panels are installed where traffic studies demand, not where columns allow. One shell, many revenue streams.

A Robust Steel Structure Guards Critical Gear

A rigid steel structure resists high winds, seismic rumbles, and flying debris far better than wood or tilt-wall. Bolted connections absorb motion while protecting rack alignment.

Steel’s non-combustible nature slows fire spread, giving crews precious minutes to respond and insurers confidence in lower risk.

Optional impact-rated cladding, reinforced entry points, and tamper-proof hardware raise defenses even higher – vital when your servers form the backbone of global commerce.

Unified Building System Keeps Projects Simple

From anchor bolts to ridge caps, our unified building system means every component is designed to work together. Roof sheets, purlins, and bracing align precisely with main frames.

Integrated engineering speeds submittals through code review, and deliveries arrive in staged loads that match erection sequences.

With one team responsible for structure, accessories, and finish trims, communication lines stay short and mistakes stay small – your schedule stays on track.

- Unified components ensure seamless integration, reducing inconsistencies on-site.

- Precise alignment of roof sheets, purlins, and bracing enhances structural efficiency.

- Streamlined engineering accelerates the code review and approval process.

- Centralized responsibility simplifies communication, cutting risks and delays.

100 x 200 Metal Building Footprint Maximizes Equipment Flow

The 100 x 200 metal building footprint offers sweeping sightlines for operators and safety techs. No hidden corners mean fewer accidents and faster response to alarms.

Extra width supports dual hot-aisle containment rows with center maintenance corridors, boosting air efficiency and technician comfort.

Wide exterior walls accept large louvers and intakes, letting you tailor airflow strategies – direct-to-chip liquid, rear-door heat exchangers, or free-air economizers – all without squeezing mechanical rooms.

Future-Ready 100×200 Steel Building Expansion Paths

A 100*200 steel building grows as fast as your data demand. Remove an end wall, add matching frames, and you gain new pods without daily operations missing a beat.

Need vertical growth? Main columns already sized for mezzanine loads easily accept second-story walkways or battery platforms.

By leveraging modular bays and standardized connections, expansions stay predictable in cost and timing – no mystery change orders, no risky retrofits.

Meeting Local Building Codes and Tough Snow Loads

From Florida hurricanes to Montana blizzards, each kit meets local building codes for wind, seismic, and snow loads. Engineering stamps arrive with your submittals, smoothing municipal approval.

Oversized gutters and downspouts manage heavy meltwater, while thermal spacers stop ice dams on insulated panels.

Designed right the first time, your facility avoids retrofit headaches and stays mission-ready even in extreme weather events.

- Customized engineering solutions ensure compliance with region-specific wind and snow load requirements.

- Pre-engineered kits simplify the approval process with certified engineering stamps included.

- Robust, weather-resistant designs minimize maintenance and retrofitting needs in extreme climates.

Complete Steel Building Package with Energy-Efficient Wall Panels

Every order ships as a full steel building package – frames, fasteners, trim, and high-R wall panels that create an airtight envelope.

These panels sandwich thick insulation between painted steel skins, delivering an energy efficient barrier that keeps chilled air where it belongs.

With fewer thermal bridges and reflective roof finishes, HVAC systems downsize, electrical bills drop, and your facility’s PUE improves year after year.

Prefabricated Steel Buildings and Metal Building Kits for Any Industry

Our prefabricated steel buildings serve more than data. They become airplane hangars, sports complexes, or even riding arenas when layouts change.

Standardized metal building kits give developers proven solutions that shorten design cycles and control budgets – whatever the end use.

These buildings offer** unmatched adaptability: swap panel colors, mix façade materials, or combine bays for creative footprints without starting from scratch.

Maverick Delivers the Best 100 x 200 Metal Buildings – Request Your Quote Today!

When uptime, budget, and growth all matter, choose the experts in 100×200 data center metal buildings. Maverick’s turnkey approach pairs pre-engineered steel buildings with hands-on support from permit to punch-out.

Our seasoned team fine-tunes every steel building kit to site loads and workflow goals, then ships on schedule with no surprises. From commercial and industrial facilities to institutional and agricultural buildings – our team of steel building experts is here to help you.

Ready to secure 20,000 feet of future-proof capacity? Contact Maverick Steel Buildings now for a fast, friendly quote and see how our steel building package turns bold plans into reliable performance.

WHY CHOOSE MAVERICK STEEL BUILDINGS

Building Custom Metal Structures Is Our Specialty.

Fast Delivery

Short turnaround time for drawings.

Full Service

Installation & Coordination in the southeast USA.

Foundation Drawings Included

Customers always receive the foundation drawings.

Premium Quality

Premium Quality Steel & parts.

Safety & Durability

Fire resistant metal buildings last a lifetime.

Cost savings

Much more cost-efficient than traditional wooden structures.

No hidden cost

100% complete quotes.

Quick & Easy

Faster and easier to construct that traditional methods.

Customizable

Attractive building finish and a wide variety of options and colors.

Maintenance Free

No need to paint or patch.

100% American Made Steel

Supporting a network of American businesses.

Environmentally Friendly

25-35% of our materials are recyclable.

Price My Building

Don’t want to wait?

Call now!

| Monday | 09:00 – 17:00 | |

|---|---|---|

| Tuesday | 09:00 – 17:00 | |

| Wednesday | 09:00 – 17:00 | |

| Thursday | 09:00 – 17:00 | |

| Friday | 09:00 – 17:00 |