60×80 Wastewater Facility Steel Buildings: Big Output in 4,800 Square Feet

Crews work faster and safer when equipment lines up in neat rows. Operators reach valves, sensors, and sample taps without climbing over pipes. That efficiency cuts exposure to chemicals and boosts uptime.

Because the frame is corrosion-protected, the shell resists spray and steam year after year. Long service life means fewer shutdowns and more focus on clean-water goals.

Controlling Building Cost with Pre-Engineered Metal Building Kits

A pre-engineered metal building is precision-cut on robotic tables, locking in predictable building cost before ground breaks. All parts ship as numbered metal building kits, so erection crews waste zero minutes hunting hardware.

Bulk fabrication lets Maverick negotiate steel at scale, passing savings to you. Clear drawings reduce change orders that can drain contingency funds.

Less time on site means lower crane rental and supervision expenses. Your finance team sees value on day one, while citizens enjoy reliable service without rate shocks.

Flexible Layouts in a 60×80 Metal Building

Every 60*80 metal building can be re-configured as regulations evolve. Open spans accept taller filter presses or longer UV banks later without structural cuts.

Exterior man-doors sit on bolted jambs, so moving an entry is as simple as relocating panels. Interior mezzanines bolt to main frames, adding office or lab space above wet zones.

Growth happens inside the existing footprint, sparing taxpayers the cost and delay of new real estate. Adaptability today ensures tomorrow’s compliance.

Engineering Metal Building Strength for Heavy Loads and Harsh Snow Loads

Process equipment vibrates, so our engineers model every beam for dynamic stress. Heavier column bases anchor pumps that cycle day and night.

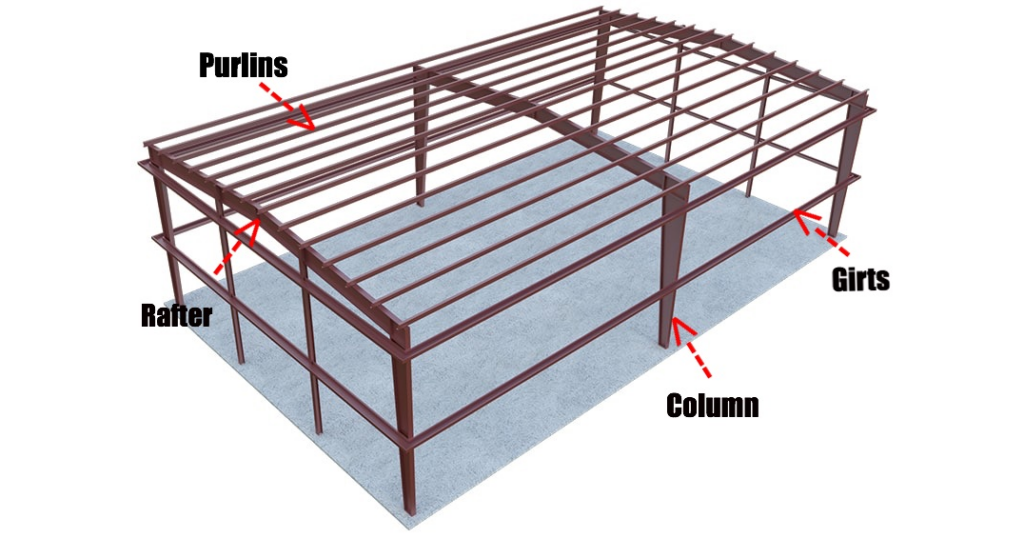

In cold regions, roof purlins and clips are sized for local snow loads plus drift. Deep-rib panels shed ice quickly, preventing ponding that can crush lesser roofs.

The result is a shell ready for blizzards and blower shake alike. Confidence in the frame keeps your attention on treatment results, not emergency repairs.

Navigating Local Building Codes for a Smooth Building Project

Permitting can stall any building project, but stamped plans meeting all local building codes move through review fast. Fire separation distances, wind maps, and seismic data are baked in from day one.

Maverick’s code experts coordinate with inspectors, answering questions before they become delays. Clear documentation builds trust and speeds approvals.

Shorter review times push groundbreaking earlier, locking loan rates and protecting budgets against market swings. The project stays on track from kickoff to ribbon-cutting.

Durable Materials and Smart Roof Style – What These Buildings Offer

Galvanized girts, stainless bolts, and factory paint protect the shell from chlorine and ammonia vapors. These buildings offer decades of low-stress service.

Choose a gable roof style for fast water runoff or a single-slope roof that funnels rain to one side for simple collection. Both options support solar panels if green power is a goal.

Wall panels lock with hidden screws, creating a clean finish that stops leaks and deters pests. The polished look reassures regulators and neighbors alike.

Pre-Cut Efficiency Saves Time per Square Foot

Every flange, clip, and stiffener arrives pre cut and labeled. Ironworkers match numbers, lift, and bolt – no field drilling. Fewer errors mean fewer do-overs.

Speedy framing lets electricians pull cable trays sooner, and plumbers mount pipe racks before weather turns. Dry-in often happens days ahead of traditional methods.

The time saved on each square foot reduces rental equipment, hotel stays, and overtime. Lower soft costs free funds for advanced monitoring or backup power.

Flow-Through Design with Wide Roll Up Doors

Process skids roll in fully assembled through broad roll-up doors. Crews avoid risky lifts over walls, cutting accident potential.

During maintenance, carts exit quickly to wash pads, keeping floors dry and safe. Air curtains limit odor and insect entry when doors stay open for deliveries.

High-cycle springs and chain operators stand up to constant use, while insulated panels maintain interior climate control. Easy access meets energy savings in one smart package.

Pick Maverick’s 60×80 Wastewater Facility Metal Buildings – Start Today!

Maverick’s 60×80 wastewater facility metal buildings blend endurance, value, and speed. Our seasoned team guides you from concept to final inspection, answering every detail with clarity.

We ship complete kits – frames, fasteners, trim – ready for rapid assembly. Support continues long after the last bolt is tight, ensuring satisfaction throughout the life of your plant.

Protect your community’s water with a partner who delivers on promises. Contact Maverick Steel Buildings now to lock your schedule, control costs, and build a facility that stands strong for generations.

WHY CHOOSE MAVERICK STEEL BUILDINGS

Building Custom Metal Structures Is Our Specialty.

Fast Delivery

Short turnaround time for drawings.

Full Service

Installation & Coordination in the southeast USA.

Foundation Drawings Included

Customers always receive the foundation drawings.

Premium Quality

Premium Quality Steel & parts.

Safety & Durability

Fire resistant metal buildings last a lifetime.

Cost savings

Much more cost-efficient than traditional wooden structures.

No hidden cost

100% complete quotes.

Quick & Easy

Faster and easier to construct that traditional methods.

Customizable

Attractive building finish and a wide variety of options and colors.

Maintenance Free

No need to paint or patch.

100% American Made Steel

Supporting a network of American businesses.

Environmentally Friendly

25-35% of our materials are recyclable.

Price My Building

Don’t want to wait?

Call now!

| Monday | 09:00 – 17:00 | |

|---|---|---|

| Tuesday | 09:00 – 17:00 | |

| Wednesday | 09:00 – 17:00 | |

| Thursday | 09:00 – 17:00 | |

| Friday | 09:00 – 17:00 |