150×300 Wastewater Facility Steel Buildings – 45,000 Square Foot Efficiency

Wide aisles also help operators service blowers without tearing out pipes. New skids roll through overhead doors, and cranes lift tanks straight to pads. The open plan trims outage time during upgrades.

Every frame is laser-drilled at the factory, so bolts slide in without reaming. Faster assembly keeps clean-water regulations on schedule and neighbors happy.

Pre-Engineered 150×300 Steel Building Kits for Cost Saving Construction

These steel building kits use robotic welders that cut waste, keeping construction costs predictable. Factory precision means crews spend hours lifting steel, not reshaping parts. Rental cranes leave the site days sooner, a direct cost saving.

Bulk material orders lock pricing early, shielding budgets from market swings. Stamped drawings pass plan review faster, reducing holding fees on borrowed funds.

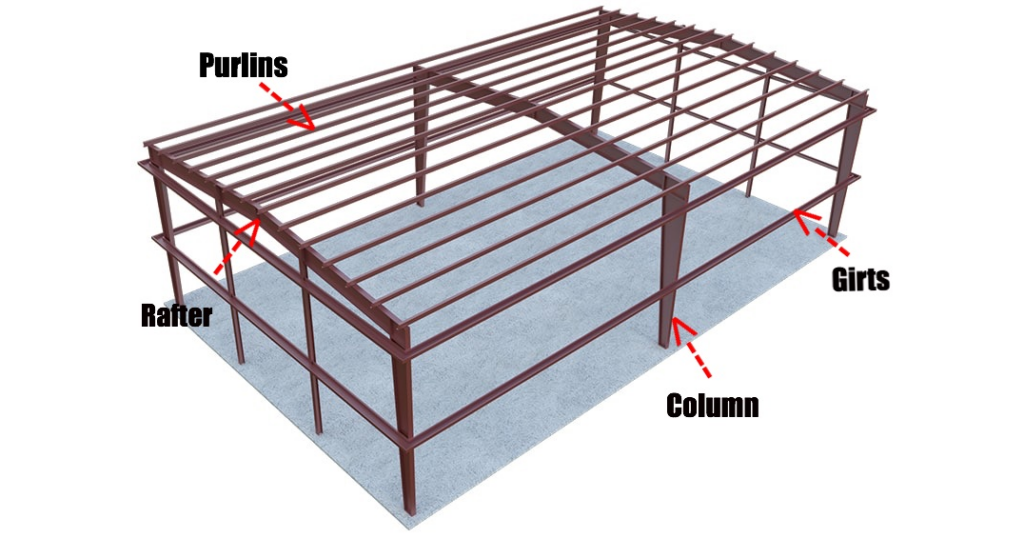

Because pieces arrive labeled by phase, trades work in tight sequence. Electricians hang cable tray right after purlins are set, while plumbers mount pipe racks before bad weather hits. Smooth flow equals smooth finance.

High Quality Steel Structures Engineered for Heavy Snow and Wind

Northern utilities face blizzards, and coastal plants battle storms. This 150*300 steel building features deep-rib panels, robust clips, and stiff braces that shrug off heavy snow drifts and hurricane gusts.

Engineers run load analysis for wind, snow, and seismic maps in your region. Roof purlins and anchor bolts are sized accordingly, protecting vital pumps from roof collapse or sway.

High-build paint and galvanized girts fight corrosion from chlorine fog. Durable coatings reduce repaint cycles and keep structures bright for decades, proving true long term value.

Flexible Design Options to Meet Tough Maintenance Requirements

Wastewater rules change quickly, so versatile design options matter. Clear spans let operators slide in taller presses or longer UV racks without torching frames. End walls unbolt to add future bays.

Overhead catwalks bolt to main columns, giving techs safe access to sensors while keeping floors clear. Mezzanines turn unused height into offices or chemical labs.

Smart layouts simplify maintenance requirements. Straight pipe runs, overhead jib rails, and roomy valve clusters cut lock-out time, speeding repairs and lowering manpower hours.

By prioritizing flexibility and practicality in design options, wastewater treatment facilities can greatly improve their long-term value and sustainability.

Standing Seam Roofs Deliver Protection with Minimal Maintenance

A weathertight standing seam roof locks panels together above the rib, hiding screws and stopping leaks. Steep pitches shed rain fast, while optional snow guards slow slide-offs in icy zones.

Factory-applied mastic seals joints for life, eliminating yearly caulk checks. Crews spend less time on ladders and more on process control.

Roof curbs arrive pre-flashed for vents and odor scrubbers. Fit-first installation avoids field cutting that can void warranties, keeping inspections easy and costs low.

Predictable Building Costs with Streamlined Project Management

Lumped-sum quotes combine steel, fasteners, and freight into one line item, clarifying total building costs on day one. Clear scopes ease funding approvals and bond sales.

Dedicated coordinators handle freight windows, crane day scheduling, and crew sequencing. This tight project management avoids idle labor and double handling.

Weekly progress calls catch issues early. Quick adjustments keep work on target, saving both calendar days and penalty fees. Owners call it a “stress-free” building project experience.

How 150×300 Wastewater Facility Metal Buildings Reduce Maintenance Costs

Rigid frames resist constant vibration from blowers, limiting weld fatigue. Smooth wall liners wipe clean after chemical splashes, preventing hidden corrosion.

LED fixtures rated for damp zones last a decade and cut energy bills in half. Fewer bulb swaps mean fewer lift rentals and downtime hours.

These choices slash maintenance costs long after the ribbon-cutting, freeing budget for lab upgrades instead of roof patches. Over the years, the savings multiply.

By investing in 150×300 wastewater facility metal buildings, owners can benefit from reduced maintenance costs. The durable rigid frames used in these buildings are able to withstand constant vibration from blowers, preventing any potential weld fatigue.

Why This Building System Outperforms Traditional Building Construction

Unlike masonry, steel goes up in any season. Winter crews weld in heated lifts while concrete block waits for spring. Earlier dry-in moves startup ahead of compliance deadlines.

Steel resists mold and termite damage that plague wood, and it flexes under seismic loads instead of cracking. That resilience keeps the plant running when disasters strike.

Because the building system is modular, expansion is easy. Unbolt a gable, add frames, and match sheets – no jackhammers, no rubble, no angry neighbors.

Partner with a Company That Specializes in Wastewater Design and Construction

Maverick is the company that specializes in steel design and construction for treatment plants nationwide. Our engineers know pipe trench loads, chemical vent codes, and lab HVAC demands.

We cross-check process layouts with frame reactions, avoiding mid-build surprises. Owners gain peace of mind because one team handles structure, drawings, and tech support.

Past clients praise the blend of expertise and friendliness. Success stories span tiny rural lift stations to regional mega-plants – all delivered on time and on budget.

Choose Maverick – Your Best 150×300 Wastewater Facility Metal Building Offers

Maverick’s 150×300 wastewater facility metal buildings merge strength, speed, and affordability. Each kit arrives complete, meets code, and stands tall against storms.

We guide you from concept sketches to final bolt-tightening, ensuring a truly high-quality, cost-saving outcome. Long warranties and live support back every order.

Ready to secure critical infrastructure with confidence? Contact Maverick Steel Buildings today to lock pricing, schedule delivery, and enjoy a 45,000-square-foot facility built for generations of clean-water service.

WHY CHOOSE MAVERICK STEEL BUILDINGS

Building Custom Metal Structures Is Our Specialty.

Fast Delivery

Short turnaround time for drawings.

Full Service

Installation & Coordination in the southeast USA.

Foundation Drawings Included

Customers always receive the foundation drawings.

Premium Quality

Premium Quality Steel & parts.

Safety & Durability

Fire resistant metal buildings last a lifetime.

Cost savings

Much more cost-efficient than traditional wooden structures.

No hidden cost

100% complete quotes.

Quick & Easy

Faster and easier to construct that traditional methods.

Customizable

Attractive building finish and a wide variety of options and colors.

Maintenance Free

No need to paint or patch.

100% American Made Steel

Supporting a network of American businesses.

Environmentally Friendly

25-35% of our materials are recyclable.

Price My Building

Don’t want to wait?

Call now!

| Monday | 09:00 – 17:00 | |

|---|---|---|

| Tuesday | 09:00 – 17:00 | |

| Wednesday | 09:00 – 17:00 | |

| Thursday | 09:00 – 17:00 | |

| Friday | 09:00 – 17:00 |