100×200 Wastewater Facility Steel Buildings – 20,000 Square Feet of Column-Free Space

Clear spans also keep pipe runs clean. Pumps, blowers, and UV units sit in neat rows, so techs reach valves fast during peak flow events. Good layout lowers accident risk and shortens service breaks.

Because the frame arrives ready to bolt, crews dry-in quickly, shielding electronics from dust and weather. Less downtime means better water quality for the community.

100×200 Wastewater Facility Metal Buildings Keep Work Moving

Factory-cut parts make 100×200 wastewater facility metal buildings fast to erect, often weeks quicker than block. Every beam is numbered, so ironworkers build the shell like a life-size model. Speed saves crane hours and hotel nights.

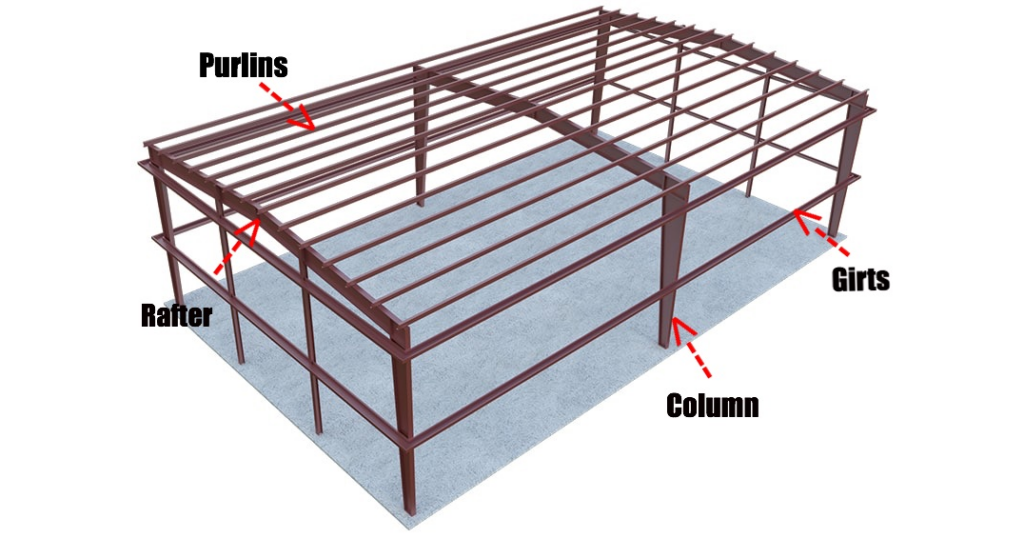

Smooth schedules help other trades. Electricians drop cable trays as soon as purlins lock, while plumbers mount pipe racks before rain hits.

Quick builds keep ratepayers happy. Faster openings mean sooner compliance with new discharge rules, protecting local streams and city budgets.

Pre-Engineered Metal Building Systems Control Steel Building Cost

A true pre-engineered metal building is drawn in 3-D before steel is cut. That precision locks the steel building cost months ahead, guarding against market swings.

Robotic welders punch holes and mill slots in one pass. Bolts slide in without reaming, so rework bills vanish.

Our steel buildings offer cost-effective solutions without sacrificing quality or durability. Each component is designed to maximize efficiency and minimize waste, ensuring a streamlined construction process. Additionally, pre-engineered metal building systems are highly customizable, allowing for adaptations to meet specific project requirements.

Metal Building Kit Delivers Cost-Effective Construction

Every Maverick metal building kit ships with framing, braces, trim, and fasteners wrapped by phase. Crews spend time lifting, not sorting.

Bulk buying drops material prices and unites freight into one shipment. Savings roll straight into the plant budget.

Fewer loose orders also cut error risk. One tracking sheet follows the load from factory gate to job site fence, protecting schedules and wallets alike.

Rugged 100 × 200 Metal Building Handles Wind, Snow, and Seismic Loads

The Gulf Coast sees hurricanes; the Rockies fight quakes; the North battles whiteouts. A 100 x 200 metal building is engineered for all three.

Braced frames stop sway, deep-rib panels shed drifts, and anchor bolts grip hard soils. Region-specific clips keep roofs tight under uplift.

When storms fade, the facility stands ready. Pumps restart fast, and the water keeps flowing clean. That resilience brings priceless peace of mind to plant managers.

Prefab Metal Buildings Provide Long-Term Reliability

Quality coatings block rust from chlorine fog and acid rinse. Tight seams stop leaks that rot insulation. Over the long term, fewer repairs mean more uptime.

LED lights rated for damp zones sip power and last a decade. High-R blankets cut heating costs in winter and cooling loads in summer.

These smart choices turn small premiums into big utility savings. Money once spent on fixes now funds better lab gear and staff training.

How Our Building System Adapts as Buildings Are Designed to Grow

Plans change. Flow rates rise and rules tighten. Our modular building system anticipates the future. End walls unbolt to add fresh bays; roof curbs accept new odor scrubbers.

Interior mezzanines bolt to main columns, creating offices or break rooms above wet wells.

Because the buildings are designed for change, you keep the same address while doubling output, avoiding costly land hunts and lengthy permits.

A 100 x 200 Steel Buildings Project with a Great Experience from Start to Finish

Friendly reps answer calls fast, walking you through codes, loads, and options. Clear quotes list every bolt, so no surprises lurk later.

During build, live support helps crews tighten tough connections or adjust openings. Problems solved in minutes, not days.

Owners rave about the journey – “a great experience,” many say – because communication stays open until the final inspection stamp.

Choose Maverick for the Best 100×200 Steel Building – Get Started Today!

Maverick’s 100*200 steel buildings for wastewater facilities deliver strength, speed, and lasting value. Each pre-engineered steel kit arrives complete, meets strict snow loads, and ships on time.

Our experts manage drawings, freight, and field questions, making complex projects feel simple. You focus on clean water; we handle the shell.

Ready for stress-free construction? Contact Maverick Steel Buildings now to lock your date, control building costs, and see how easily a top-tier facility can rise on your site.

WHY CHOOSE MAVERICK STEEL BUILDINGS

Building Custom Metal Structures Is Our Specialty.

Fast Delivery

Short turnaround time for drawings.

Full Service

Installation & Coordination in the southeast USA.

Foundation Drawings Included

Customers always receive the foundation drawings.

Premium Quality

Premium Quality Steel & parts.

Safety & Durability

Fire resistant metal buildings last a lifetime.

Cost savings

Much more cost-efficient than traditional wooden structures.

No hidden cost

100% complete quotes.

Quick & Easy

Faster and easier to construct that traditional methods.

Customizable

Attractive building finish and a wide variety of options and colors.

Maintenance Free

No need to paint or patch.

100% American Made Steel

Supporting a network of American businesses.

Environmentally Friendly

25-35% of our materials are recyclable.

Price My Building

Don’t want to wait?

Call now!

| Monday | 09:00 – 17:00 | |

|---|---|---|

| Tuesday | 09:00 – 17:00 | |

| Wednesday | 09:00 – 17:00 | |

| Thursday | 09:00 – 17:00 | |

| Friday | 09:00 – 17:00 |