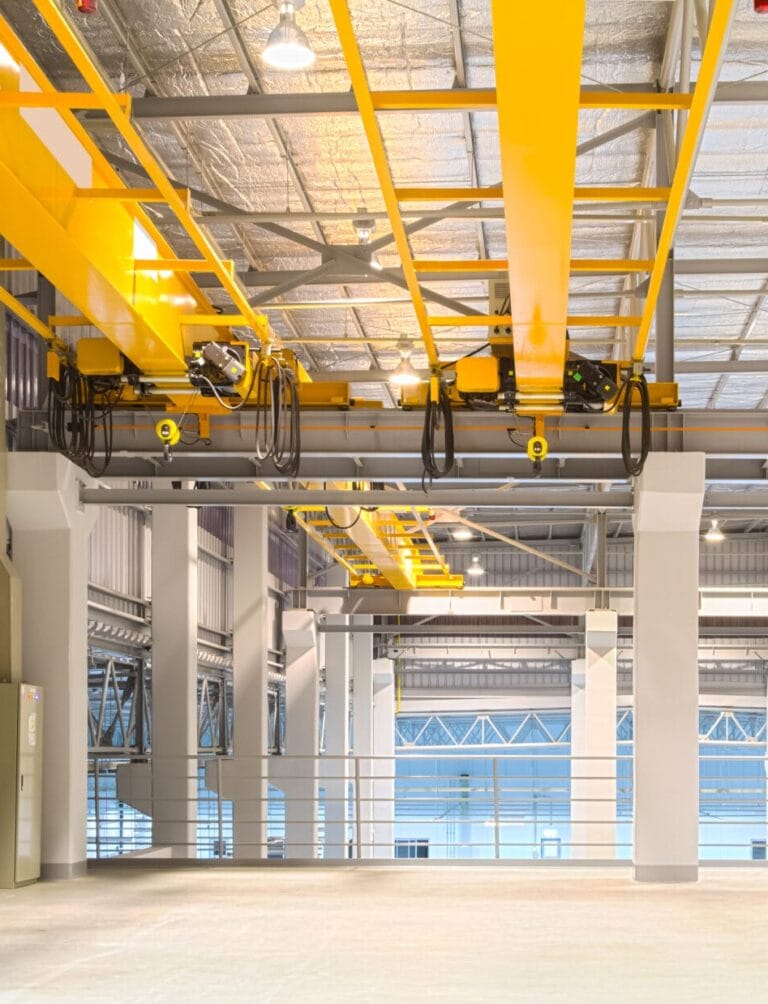

What “crane‑ready” means

A crane‑ready metal building integrates runway beams and rails with the primary steel frame so vertical and lateral loads from crane motions flow safely to the foundations. The shell is engineered to your local building codes, with member sizes and bracing patterns selected for crane tonnage, service class, and anticipated usage cycles. Get your pre engineered steel building with 100% American‑made steel from Maverick Steel Buildings to ensure predictable performance over decades of heavy service.

Set the right hook height and eave height

Start with the hook height required for your process, clearance over the tallest load when lifted and back into eave height and runway elevation. Factor in:

End approach at each runway end so the hook can reach near columns.

Top approach to avoid collisions with roof structure, lights, or ductwork.

Maintenance access for cranes and runway rails.

When hook height and clearances drive eave height higher, your steel tonnage increases. Optimizing bay spacing and roof profile can help offset that added steel.

Our company, Maverick Steel Buildings, specializes in high-quality prefabricated steel building kits that are easy to assemble and will last a lifetime. Get a free quote on our premium steel horse barn kits today!

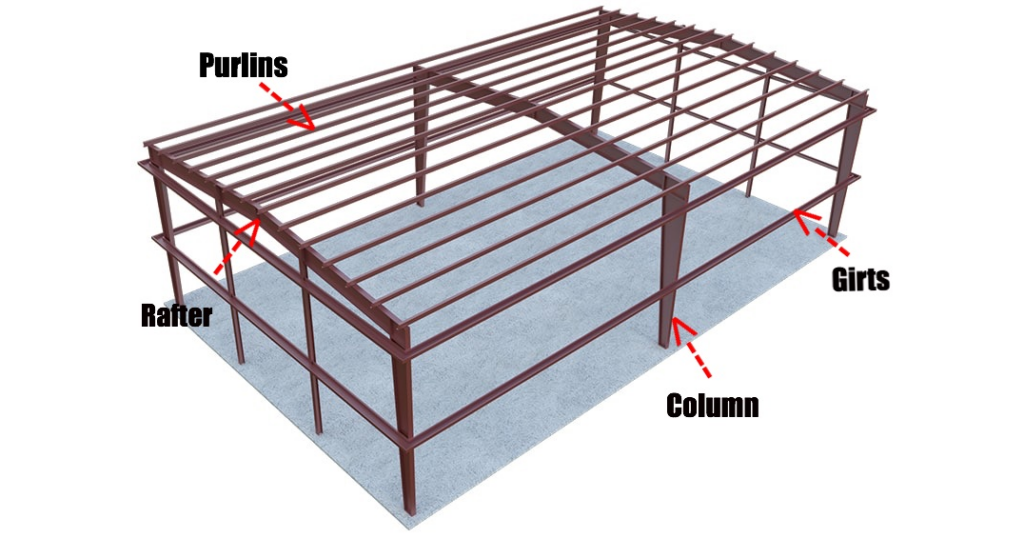

Bay spacing, frames, and sway control

Many light‑ to mid‑capacity systems (5–20 tons) run well with uniform bays; heavier systems may need portal frames, X‑bracing, or moment frames in selected bays to control sway and torsion. Every crane system adds lateral forces; the building’s bracing plan must handle trolley acceleration, braking, skewing, and load swing without uncomfortable drift.

Runway beams, columns, and foundations

Runway beams are sized for wheel loads and impact factors. Supporting columns and their base plates, anchor rods, and footings must carry the combined vertical plus lateral demand at crane columns. Foundation drawings included with your kit help the concrete contractor coordinate pier sizes, embed elevations, grout, and tolerances for rail alignment.

Power, lighting, and safety coordination

Crane building systems bring a dense services layer that should be coordinated before fabrication:

Bus bar or festoon power clear of the hook envelope.

Lighting layouts that avoid glare at the operator’s line of sight and maintain clearances above the trolley.

Ventilation and HVAC placed to prevent conflict with runways.

Fall‑protection tie‑offs and catwalks for inspection access.

Bumpers, rails, and guard systems at columns and mezzanines to protect people and steel.

Cost and schedule considerations

Crane‑ready building projects cost more than conventional shells because of heavier members, bracing, and runway steel. Expect price sensitivity to tonnage, hook height, bay spacing, and service class. Maverick’s short drawing turnaround and included foundation drawings ease early coordination so you can order steel with confidence and keep erection on schedule.

Choosing the right crane and runway details

Different applications prefer different crane classes. Light assembly often pairs with CMAA Class C, while fabrication and heavy service skew toward Class D or E. We coordinate runway centerlines, column offsets, and girder depths so hook travel reaches the work envelope without clipping lights or ducts. Rail selection, ASCE rail or square bar, impacts wheel wear and alignment tolerance, and we’ll align those choices with your maintenance plan.

Tolerances and quality checks

Crane systems are only as good as their alignment. We call out anchor bolt locations, grout pads, and runway elevations on your foundation drawings so your concrete subcontractor can hold tight tolerances. During erection, our drawings indicate shim locations and camber allowances, and we recommend verification of runway straightness and cross‑level before electrification.

Futureproofing and service access

Crane capacity tends to creep up over time. If your process may grow, we can upsize select members today or design connection details that accept a higher‑capacity runway later. Catwalks and platforms at runway elevation simplify inspections and trolley maintenance, reducing downtime and lift equipment rentals in the years ahead.

Real-world examples of what changes the steel

Even small shifts in spec can alter the frame. Moving from a 5‑ton to a 10‑ton bridge, adding a longer runway, or raising hook height by 2 feet each drive member sizes and bracing choices. Conversely, clustering the heaviest picks in one bay or scheduling the most demanding lifts in a defined zone can keep steel efficient. We’ll help you model those trade‑offs so you purchase only what you need, without painting yourself into a corner later.

Smooth path to permits and fabrication

Because crane steel structures touch multiple trades, we drive early alignment with your crane vendor, electrical contractor, and mechanical team. That coordination is reflected in submittal packages your reviewers can parse quickly, accelerating permits and clearing the way for fabrication and delivery.

WHY CHOOSE MAVERICK STEEL BUILDINGS

Building Custom Metal Structures Is Our Specialty.

Fast Delivery

Short turnaround time for drawings.

Full Service

Installation & Coordination in the southeast USA.

Foundation Drawings Included

Customers always receive the foundation drawings.

Premium Quality

Premium Quality Steel & parts.

Safety & Durability

Fire resistant metal buildings last a lifetime.

Cost savings

Much more cost-efficient than traditional wooden structures.

No hidden cost

100% complete quotes.

Quick & Easy

Faster and easier to construct that traditional methods.

Customizable

Attractive building finish and a wide variety of options and colors.

Maintenance Free

No need to paint or patch.

100% American Made Steel

Supporting a network of American businesses.

Environmentally Friendly

25-35% of our materials are recyclable.

Price My Building

Don’t want to wait?

Call now!

| Monday | 09:00 – 17:00 | |

|---|---|---|

| Tuesday | 09:00 – 17:00 | |

| Wednesday | 09:00 – 17:00 | |

| Thursday | 09:00 – 17:00 | |

| Friday | 09:00 – 17:00 |