Why steel excels for last‑mile

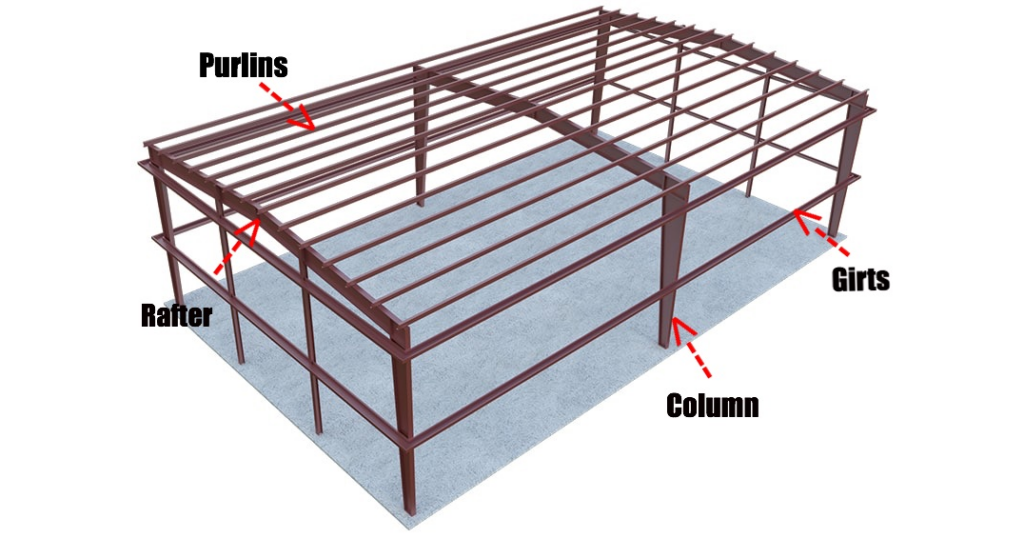

As a leading metal building supplier, Maverick’s clear-span pre engineered steel frames provide wide, column‑free interiors that adapt to pick modules, mezzanines, and return processing. As your mix changes—B2C parcels one season, store replenishment the next—the same shell can reconfigure without structural surgery. Short drawing timelines help you secure permits and installation windows in dense markets where lead time is everything.

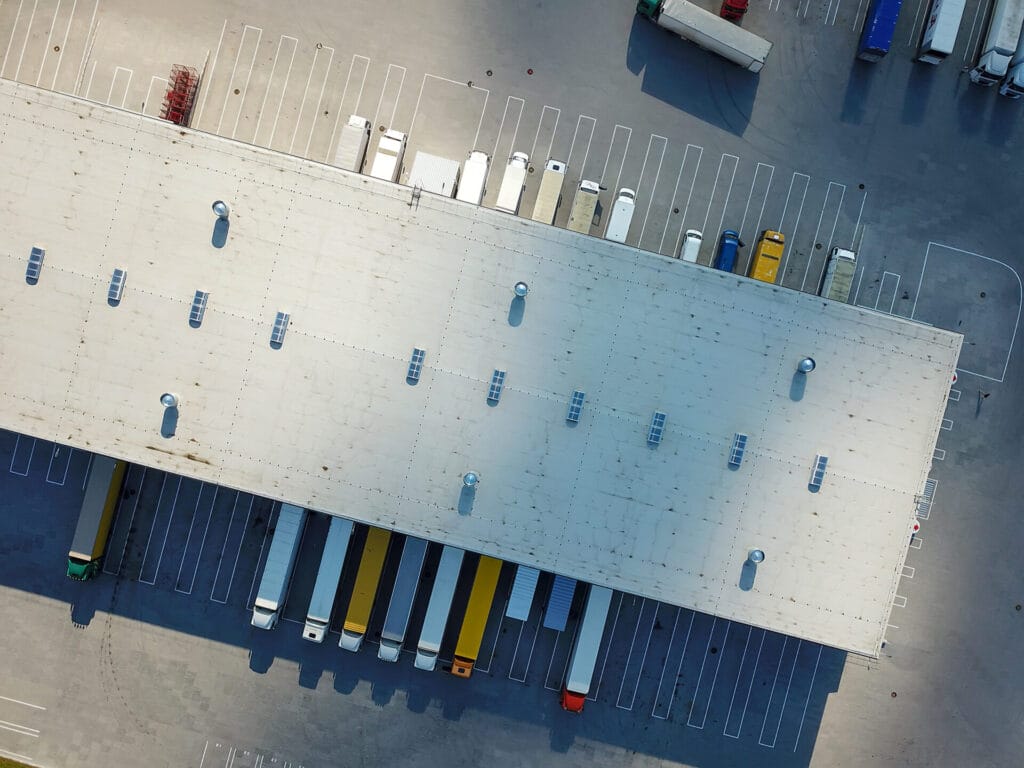

Site‑smart planning

Many last‑mile sites are constrained by neighborhood streets and odd parcel shapes. Plan for:

Right‑sized dock and grade doors with quick‑change panels if the ratio shifts over time.

One‑way circulation to keep vans and box trucks flowing around the building.

Separate employee and fleet parking, with EV charging zones if required.

Secure yards and compact staging lanes for early‑morning waves.

Mezzanines, clear heights, and pick modules & Door density and staging

For micro-fulfillment, clear heights—often 24’–32’—should be chosen to fit intended equipment and mezzanine loads. Steel construction simplifies the addition or expansion of mezzanines, and column-free spans optimize U-shaped and L-shaped pick paths. It is also essential to reserve overhead pathways for critical infrastructure like conveyor, cable tray, and sprinkler mains, and plan for catwalk access for maintenance. Given the high parcel volumes, micro-fulfillment centers require a greater density of openings per square foot than traditional distribution centers. This high door density must be balanced with sufficient interior staging space to prevent operational bottlenecks. Using vertical-storing levelers and insulated, fast-cycle doors helps maintain quick turns while minimizing air exchange.

Power, HVAC, and data & Cost and schedule factors

Micro‑fulfillment relies on uptime. Reserve roof and platform space for RTUs, exhaust, and future capacity, and route power with busways or overhead trays to keep the floor flexible. If you plan automation, coordinate penetrations and loading for conveyors, AMRs, or shuttles before fabrication so you don’t revisit the steel later. On compact sites, small changes in door mix or clear height can swing cost and schedule. Early selections let Maverick issue drawings fast; included foundation drawings keep slab, joints, and anchor locations aligned with the frame so the build can proceed without rework.

Micro-Fulfillment Steel Buildings: Optimized for Site, Urban Constraints, and Comfort

Send your parcel volumes, door targets, and site plan. We’ll design a micro-fulfillment shell that fits today’s routes and tomorrow’s growth. Tight parcels and neighbor constraints demand quiet, clean, and good-looking buildings. We offer façade treatments and color options that blend with retail corridors, plus thoughtful placement of RTUs and exhaust so rooflines stay tidy. Interior noise control can be improved with liner panels and insulation without adding complex assemblies. High-tempo facilities still need safe, comfortable workspaces. Clear sightlines across pick modules, non-slip floor finishes at docks, and designated break areas away from vehicle routes make daily operations smoother. Thoughtful daylighting through translucent panels reduces lighting loads and improves morale on long shifts.

Phased Construction and Leasing Flexibility

To accelerate your opening, we can phase construction, delivering the core and shell with pre-planned openings for future expansion like mezzanines or docks. This allows for a quick pilot operation with early electrical service and simple demising. For multi-tenant assets, we design with predictable module widths and storefront rhythms to ensure spaces split cleanly and allow tenants to easily convert from grade access to dock loading, making the leasing process faster and more flexible for owners and developers.

Streamlined Process and Future-Ready Buildings

You’ll get a clear schedule, a dedicated point of contact, and staged drawing releases—anchor bolt plans first, then fabrication drawings—so civil and concrete can mobilize while the balance of details finalize. That cadence keeps city approvals moving and shaves weeks off time to beneficial use. We’ll sequence punch‑list items around your first‑wave inventory so crews are never in your way. Door cycles, leveler performance, lighting levels, and life‑safety checks are documented, and you receive as‑built drawings that show penetrations, curbs, and spare capacity locations.

As delivery promises tighten and order profiles evolve, your building should evolve with them. With a clear‑span steel shell and smart provisions for doors, mezzanines, and power, you can pivot quickly—without tearing into the steel structure or pausing operations. When volumes grow or the tenant mix shifts, those references make the next improvement phase faster and cheaper.

WHY CHOOSE MAVERICK STEEL BUILDINGS

Building Custom Metal Structures Is Our Specialty.

Fast Delivery

Short turnaround time for drawings.

Full Service

Installation & Coordination in the southeast USA.

Foundation Drawings Included

Customers always receive the foundation drawings.

Premium Quality

Premium Quality Steel & parts.

Safety & Durability

Fire resistant metal buildings last a lifetime.

Cost savings

Much more cost-efficient than traditional wooden structures.

No hidden cost

100% complete quotes.

Quick & Easy

Faster and easier to construct that traditional methods.

Customizable

Attractive building finish and a wide variety of options and colors.

Maintenance Free

No need to paint or patch.

100% American Made Steel

Supporting a network of American businesses.

Environmentally Friendly

25-35% of our materials are recyclable.

Price My Building

Don’t want to wait?

Call now!

| Monday | 09:00 – 17:00 | |

|---|---|---|

| Tuesday | 09:00 – 17:00 | |

| Wednesday | 09:00 – 17:00 | |

| Thursday | 09:00 – 17:00 | |

| Friday | 09:00 – 17:00 |