Why Steel Is the Natural Fit for Flex Industrial Buildings

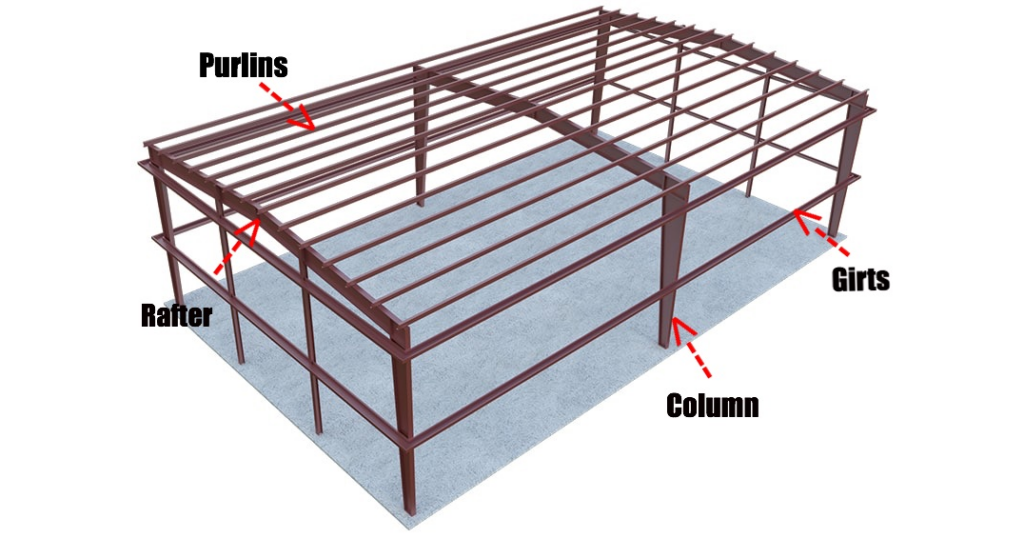

Flex steel building projects evolve. Their steel frames provide column-free interiors for a better long term investment, straightforward demising, and predictable schedules so you can lease space sooner. When tenants shift, door mixes change, or office footprints grow, the structure remains ready—no invasive surgery required.

Module Planning, Bay Strategy, and Tenant Infrastructure

Start with a bay width that fits standard tenant modules, commonly 40′-50′, so flex spaces divide cleanly and storefronts align. Keep the front office/showroom at the street elevation with rear loading for docks and grade doors. Use pre-planned demising locations with embedded steel to accommodate future partitions without rework.

Plan wet columns and utility trunks at predictable intervals so each bay can receive domestic water, power, data, and gas without crossing demising lines. Overhead busway or cable tray keeps floors flexible while allowing quick tenant build-outs. If labs or light manufacturing are likely, pre-plan for exhaust ducts, make-up air, and roof curbs in logical banks.

Storefronts, Façades, and Design That Leases

Flex spaces succeed when they look good and adapt quickly. Choose storefront systems, canopies, and parapet profiles that support brand expression while keeping water tight. Inside, spec utility chases and drops that allow tenants to add conference rooms, labs, or assembly areas without cutting into structure.

First impressions matter. Flexible façade modules support a range of tenant identities while keeping structure efficient behind the scenes. Clear signage zones, covered entries, and lighting that presents well at night make your park easy to market and pleasant to occupy. Inside, exposed red-iron framing with clean liner panels creates a modern, durable aesthetic tenants appreciate.

Clear Heights, Mezzanines, Comfort, and Sustainability

Typical flex shells run 24’–32′ clear, leaving room for mezzanines over office or light production zones. Coordinate stair locations and guardrail with egress plans. Keep roof loads and penetrations organized so future RTUs, exhaust, or solar can be added without relocating structural members.

Insulation strategies, which drive energy efficiency, well-placed RTUs, and daylighting options combine to create comfortable spaces that lease faster and keep operating costs predictable. If you plan to pursue incentives or certifications, we’ll coordinate cool roofs (like standing seam), solar-ready zones, and skylight patterns with fall-protection anchors so safety and sustainability work together.

Loading, Circulation, and Everyday Operations

Balance dock and overhead doors (grade doors) based on your tenant profile. Plan truck courts for single or dual-lane circulation and separate employee/customer traffic for safety. Add site lighting and fencing where after-hours operations are expected. Use bollards and rails to protect openings and MEP equipment along the perimeter.

Once your tenants move in, the right shell keeps headaches low. Clear loading zones, protected MEP runs, and obvious egress paths mean fewer service calls and smoother fire inspections. When a suite turns over, demising and re-branding moves quickly—your investment keeps producing without long, expensive gaps between leases.

Growth, Conversion, and Delivery in Phases

Steel makes it easy to add bays at an end wall or to re-stripe interiors as your mix changes. If a single tenant expands, remove demising walls and convert doors; if the park densifies, add demising and more storefronts. Early planning for future connections reduces downtime later.

If your absorption forecast is staged, we’ll design phaseable end walls and connection points so you can build in segments without rework. Foundations and utilities can be planned for the full build-out while erecting steel in manageable, finance-friendly steps.

Why Maverick for Flex Industrial Projects

To secure a flex industrial steel buildings project cost effectively, consider that costs depend on façade treatments, storefront length, clear height, and local code loads. Maverick is one of the leading steel building companies whose fast drawings and included foundation drawings help you secure approvals quickly, compressing the time from sitework to ribbon cutting.

- Engineered to your location’s codes for wind, snow, and seismic.

- 100% American-made steel with clear-span frames ready for change.

- Foundation drawings included and quick design turnarounds to keep momentum.

From the first site plan review through anchor bolt placement and steel delivery, you’ll have a step-by-step path and a responsive team. You’ll know when to expect drawings, what information we need, and how to keep inspections moving so you can open on schedule.

Send your site plan, target bay width, door mix, and ZIP code. We’ll translate your leasing strategy into a steel package that’s easy to lease, easy to run, and easy to grow.

WHY CHOOSE MAVERICK STEEL BUILDINGS

Building Custom Metal Structures Is Our Specialty.

Fast Delivery

Short turnaround time for drawings.

Full Service

Installation & Coordination in the southeast USA.

Foundation Drawings Included

Customers always receive the foundation drawings.

Premium Quality

Premium Quality Steel & parts.

Safety & Durability

Fire resistant metal buildings last a lifetime.

Cost savings

Much more cost-efficient than traditional wooden structures.

No hidden cost

100% complete quotes.

Quick & Easy

Faster and easier to construct that traditional methods.

Customizable

Attractive building finish and a wide variety of options and colors.

Maintenance Free

No need to paint or patch.

100% American Made Steel

Supporting a network of American businesses.

Environmentally Friendly

25-35% of our materials are recyclable.

Price My Building

Don’t want to wait?

Call now!

| Monday | 09:00 – 17:00 | |

|---|---|---|

| Tuesday | 09:00 – 17:00 | |

| Wednesday | 09:00 – 17:00 | |

| Thursday | 09:00 – 17:00 | |

| Friday | 09:00 – 17:00 |