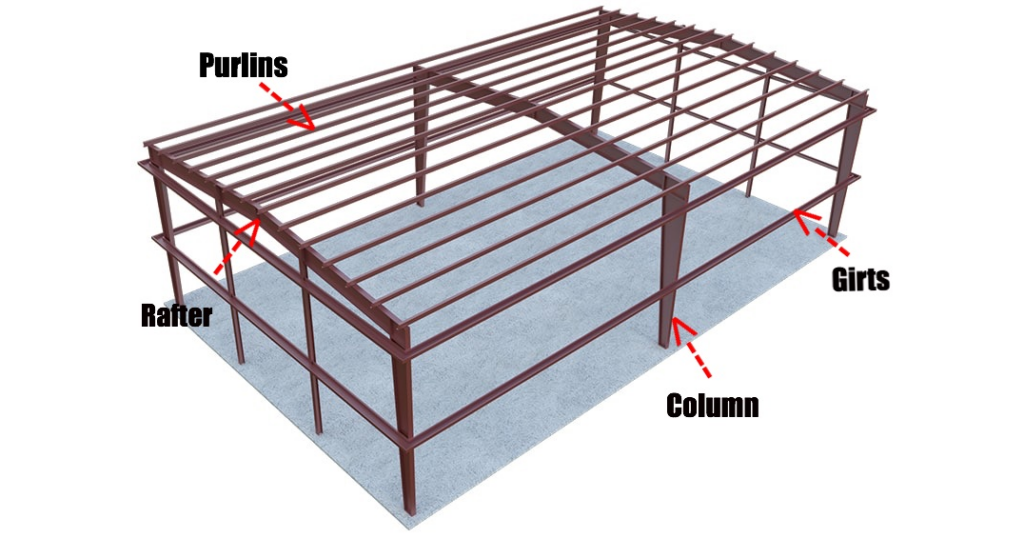

A typical strip mall steel building kit from Maverick includes primary and secondary steel framing, wall and roof panels, framed openings, fasteners, and detailed erection drawings, plus foundation drawings to align your site work and permitting.

You get a coordinated package designed to work as a system, not a pile of parts to figure out in the field. When you are ready to move forward, share your site plan, square footage, clear height, and façade goals. Our team will prepare a detailed proposal so you can review options and get your free quote started today.