WASTEWATER TREATMENT: PRE ENGINEERED STEEL BUILDINGS

Wastewater facilities demand tough shells that never slow vital treatment process work. Our wastewater facilities steel buildings use a pre engineered metal building system that ships ready to bolt, so crews finish fast even on tight budgets. Clear spans keep piping runs straight and equipment easy to access.

Because every frame is cut by robots, the finished building design meets or exceeds code on the first inspection. Panels arrive pre-drilled and labeled, trimming crane time and surprise extras. Owners see dependable strength without the headaches of block or tilt-wall.

The result is a scalable building kit that grows with changing regulations and flow rates. You save money up front and avoid costly shutdowns later. That’s a truly cost effective path to cleaner water for your community.

STEEL BUILDINGS FOR WASTEWATER TREATMENT FACILITIES

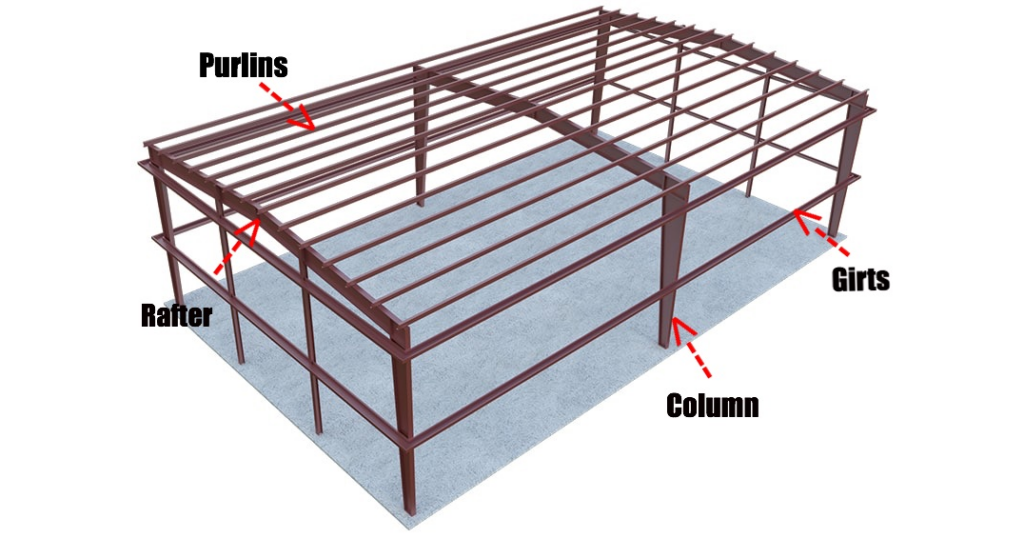

A modern steel building for wastewater treatment must protect pumps, tanks, and lab spaces from harsh chemicals. Galvanized girts, painted panels, and stainless fasteners create armor that resists corrosion year after year.

Wide doors and overhead rails speed equipment swaps, cutting downtime during upgrades. Natural light panels brighten aisles, lowering power bills and boosting staff morale on long shifts.

Behind the scenes, our engineers map loading points around clarifiers and blowers. This smart building design keeps floors stable even when heavy vessels settle or seismic waves roll through.

Cost-Effective Prefabricated Metal Building Solutions

Rising material prices squeeze public budgets. Our prefabricated metal building approach slashes site labor and waste, turning steel prices into savings instead of stress.

Factory production keeps quality high and errors low, so install crews stay small. Less manpower equals fewer hotel nights, fuel costs, and paperwork hours.

Bulk ordering also unlocks competitive pricing on insulation, louvers, and insulated doors. You stretch every tax dollar further while still delivering a first-class plant your neighbors can trust.

High-Quality Building Kits for Critical Treatment Processes

Clean water is non-negotiable, so every weld, bolt, and panel must be high quality. Maverick inspects steel twice – at the mill and before it leaves our yard.

Rigid frames stand tall against hurricanes, heavy snow, and constant vibration from aeration blowers. Panels lock tight to block pests and rain, protecting sensitive lab gear inside.

Owners rest easier knowing their facility buildings carry long warranties backed by a nationwide supply chain. Reliability here means smoother permits and happier ratepayers.

Energy-Efficient Steel Buildings for Sustainable Water Treatment

Utility bills can dwarf payroll at wastewater treatment plants. High-R roof panels and wall blankets trap conditioned air, while cool-roof finishes bounce heat away.

Daylight strips reduce lamp hours, and ridge vents exhaust humid air without fans on mild days. These upgrades create truly energy efficient operations that free cash for plant improvements.

Smart sensors dim LEDs and ramp HVAC only when workers enter, matching climate control to shift schedules. Savings add up month after month, boosting the plant’s green credentials.

Engineering Metal Building Excellence with a Qualified Team

Complex loads from digesters and sludge presses require sharp math. Our qualified team of registered engineers models every beam under full live load and worst-case wind.

Finite-element software pinpoints stress hot spots, allowing small steel increases that avoid costly over-builds. Strength goes where needed – nowhere else.

This precision delivers lighter, safer frames that arrive on schedule. Your team of experts can focus on process equipment instead of worrying about the roof overhead.

Smooth Delivery for Any Building Project with Modular Metal Building Kits

Every building project starts with clear drawings, packed bundles, and easy-to-read labels. Truck sequencing matches the crane plan, so parts land the hour they’re needed.

Modular metal building kits simplify staging on crowded sites, keeping roadways clear for chemical deliveries and routine plant traffic.

If capacity must grow, crews unbolt end walls and add new bays without stopping the plant. Flexibility like this keeps compliance high while budgets stay lean.

Choose Maverick – The Company That Specialized in Wastewater Facility Buildings

Clean water can’t wait. Maverick is the company that specialized in engineering metal building solutions for vital treatment facilities nationwide.

We blend high quality steel, competitive pricing, and a service-first mindset that keeps clients returning. From permit to punch-out, our team of experts supports every decision.

Ready to secure a durable, cost effective shell for your plant? Contact Maverick Steel Buildings today for a fast quote and see why municipalities trust us for their most critical infrastructure.

WHY CHOOSE MAVERICK STEEL BUILDINGS

Building Custom Metal Structures Is Our Specialty.

Fast Delivery

Short turnaround time for drawings.

Full Service

Installation & Coordination in the southeast USA.

Foundation Drawings Included

Customers always receive the foundation drawings.

Premium Quality

Premium Quality Steel & parts.

Safety & Durability

Fire resistant metal buildings last a lifetime.

Cost savings

Much more cost-efficient than traditional wooden structures.

No hidden cost

100% complete quotes.

Quick & Easy

Faster and easier to construct that traditional methods.

Customizable

Attractive building finish and a wide variety of options and colors.

Maintenance Free

No need to paint or patch.

100% American Made Steel

Supporting a network of American businesses.

Environmentally Friendly

25-35% of our materials are recyclable.

Price My Building

Don’t want to wait?

Call now!

| Monday | 09:00 – 17:00 | |

|---|---|---|

| Tuesday | 09:00 – 17:00 | |

| Wednesday | 09:00 – 17:00 | |

| Thursday | 09:00 – 17:00 | |

| Friday | 09:00 – 17:00 |